The term "inverted shock absorber" is often seen in magazines etc.

"What really are inverted shocks?"

"What is the point of inverting the system?"

TEIN, the suspension specialist, answers to all.

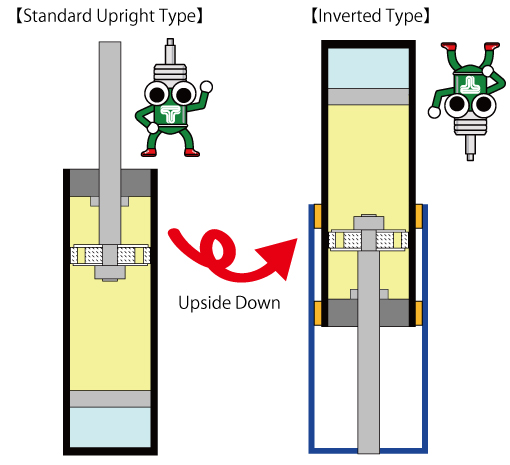

What is inverted type?

Well, many probably are wondering...

"What exactly are standard upright types and inverted types anyway?"

Put simply,

the standard upright type has a shock absorber placed upward, while the inverted has it downward.

"For what purpose and/or under what condition the inverted type is required, then?"

Let us explain step by step.

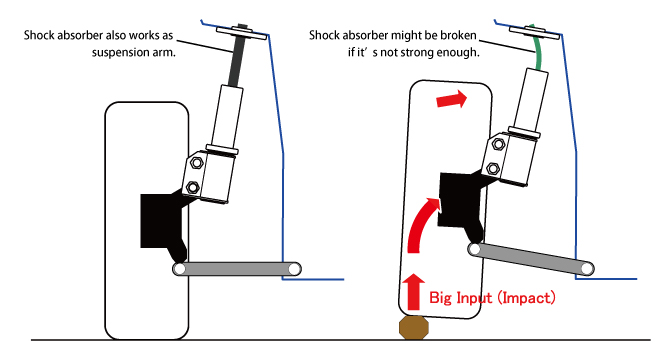

Strut suspension requires strength

Simplified Image of Strut Suspension

MacPherson strut is a type of suspension system most commonly used for the front suspension of various vehicles. With this system, the shock absorber itself also works as a part of suspension arm; hence maintaining sufficient strength is absolutely imperative. If it does not have enough strength, it not only has negative effect on car's controllability but also causes breakage of suspension leading to a major accident.

How to secure sufficient strength?

Twin-tube system, widely adopted in OE suspensions, uses thicker piston rod to ensure strength in strut types. Because of its structure, gas pressure can be kept low even with thicker piston rod used and thus the adverse effects on ride comfort can be minimized.

But the story is quite different for mono-tube system.

For its structural reasons, piston rod can not easily be made thicker.

What are the reasons, then??

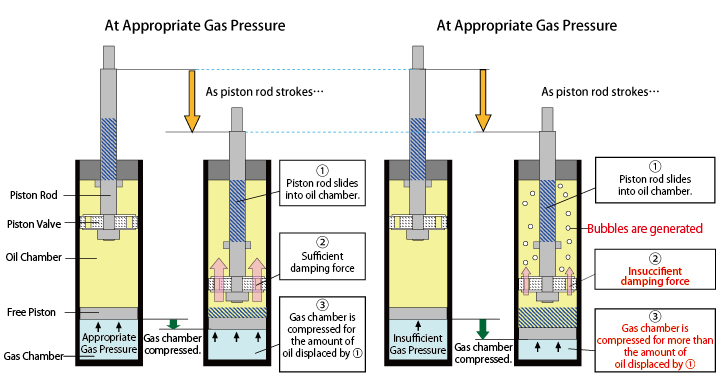

General Mono-Tube Structure

In most commonly-used mono-tube structure, both compression & rebound damping force is generated only at the piston valve. Because of this, compression damping force can not be generated properly if the gas pressure is not sufficient.

So, the higher the gas pressure, the better?

No. It's not that simple.

If the gas pressure is too high, the repulsive force and friction increase, thus causing the ride to worsen.

As you can see, mono-tube structure can only work well at finely-balanced gas pressure.

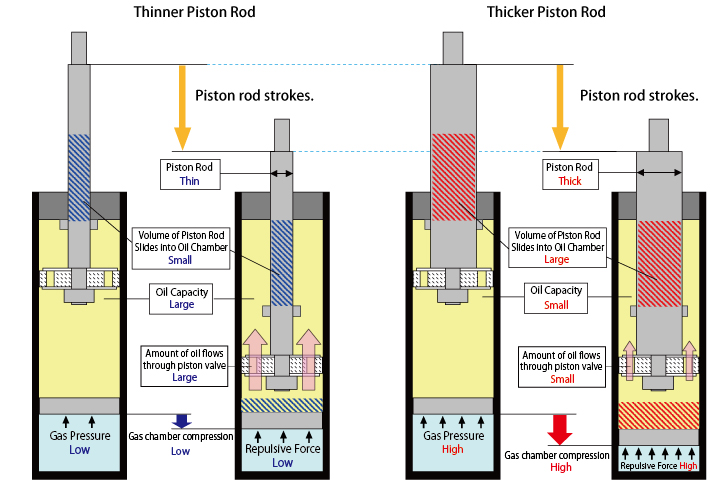

What happens if ticker piston rod is used in upright mono-tube damper...?

Would just making the piston rod thicker in the upright mono-tube struts work to secure the strength?

Compared to the thinner piston rod, the volume of piston rod slides into the oil chamber is larger and hence the gas chamber is compressed more and the repulsive force increases.

Also, the amount of oil would be smaller as the piston rod volume increases, thus one of the benefits of mono-tube structure "larger oil capacity" can not be fully utilized.

Further more, the amount of oil flows through the piston valve is less with the thicker piston rod used, for the same stroke distance, thus the damping force can not be generated stably.

To overcome, the gas pressure should be increased, but that would lead to worsening of the ride quality.

This poses a dilemma;

If possible, the piston rod should not be much thicker, in order to prevent a decline in performance. The piston rod needs to be thicker to some extent, to secure a sufficient strength.

Weighing the strength against the performance, there need to be some compromise on the damper design.

So, with the standard upright mono-tube system, widening the piston rod only makes the demerits worse. It would not be an overstatement to say that there is no advantage in using mono-tube system this way.

(This does not apply to some standard upright mono-tube system with wider piston valves, shorter strokes and/or reservoir tanks, because of sufficient room for installation, such as for racing-use shocks. Abovementioned disadvantage can be eliminated in such cases. )

Just for the reference, most of overseas super low-price mono-tube height adjustable dampers widely available on the market nowadays use standard upright system for struts.

One of the investigated samples uses dia.20 piston rod in upright mono-tube system for front struts on 86/BRZ.

This is thinner than the original shocks, which use dia.22 piston rod.

If the high-strength material is used, the use of the thinner rod would probably not be any problem.

If the same material is used, it is obvious that this one is of lesser intensity than OE components.

With these facts, you can catch a glimpse of the reasons why mono-tube strut cannot use the thicker piston rod.

Balancing strength and performance?

How can both the strength and the performance of mono-tube struts be satisfied?

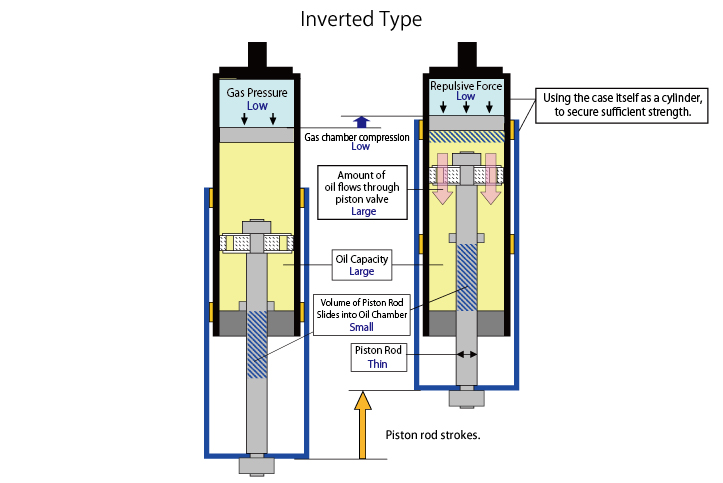

The answer is to use a separate pipe for reinforcement, just as with the inverted systems.

As shown in the picture, a large pipe is used as a sliding cylinder and adds strength against lateral force. This allows securing the sufficient strength without the use of thicker piston rod and without sacrificing the performance and the merits like large oil capacity.

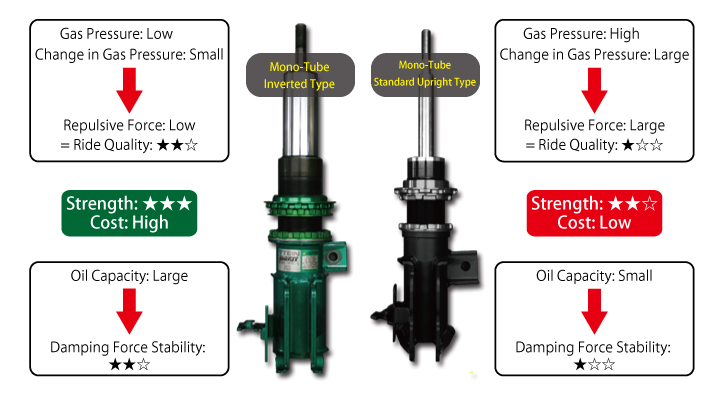

Then, why do those low-price mono-tube struts not use the inverted system, but use the standard system with lots of compromises?

The main reason is that the standard upright type uses fewer parts and thus the cost is lower.

The standard upright system is cheaper to make than the inverted system which uses more parts and requires complicated assembly process of high accuracy.

The performance comes first for TEIN products.

In the past, mono-tube strut generally meant inverted system, but this is no longer true as more and more low-price standard upright mono-tube shocks came into the market.

To get the most out of mono-tube systems for strut suspensions, TEIN strongly recommends choosing "inverted" types which provide both the sufficient strength and the high performance.

With the performance of shock absorbers being the first priority, TEIN uses "inverted" systems for all mono-tube strut suspensions.

We are sure that all TEIN users can fully enjoy the performance of mono-tube dampers to the full extent, as the skilled TEIN staffs at the factory in Yokohama are putting all the high-quality and high-prcision parts together one by one in a very careful manner.

You might feel that the inverted mono-tube dampers we offer is bit expensive, compared to those super low-price products. But please rest assured that we are making utmost efforts to offer products which are safe and highly reliable for everyone. We'll be working harder to provide better products at more affordable price, with further research and development efforts.